High Performance Key Components for galvanization & metallurgical technology

High Performance Key Components for galvanization & metallurgical technology

Galvanization & metallurgical technology

Applications

In extrusion casting line for: ingot, bloom, beam-blank and billet plants

Ranges of dimensions

- Outer diameter: min.: 130 mm, max.: 450 mm

- Inner diameter: min.: 60 mm, max.: 350 mm

- Maximal cast weight: 600 kg

- Maximal length: 2,210 mm

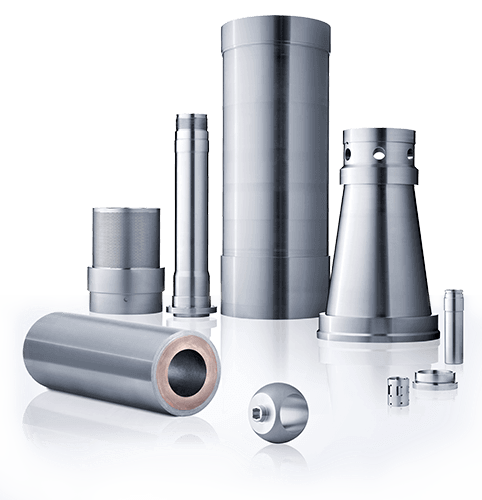

Components

Guide rollers for all parts of extrusion casting lines, with or without internal cooling, in mono-cast or combined (bi-metal) configuration

Special requirements of the materials used

Depending on segment: high resistance to corrosion, high wear-resistance, heat-resistance, resistance to thermal fatigue and good welding properties

Material groups

Austenite, martensite, duplex, composite casting (bi-metal)

Materials

1.4569, 1.4317 ( 1.4313 ), 1.4470 ( 1.4462 ), KVG "X"*

* Materials listed in italics are those that consist of our material-matched forged alloys

We are happy to answer your questions on the subjects of stainless steel processing and manufacture components according to your ideas for decanter construction, shipbuilding, engine construction and much more.

Just contact us

+49 (0)2195 92988-0

infonothing@kuhn-zerspanungstechnik.com