High Performance Key Components for Decanters

High Performance Key Components for Decanters

Decanter & separation technology

Applications

Pharmaceutical industry, biotech sector, treatment of liquid sewage and paint slurry, preparation of cooling emulsions, plastics recycling, food industry

Ranges of dimensions

- Outer diameter: min.: 50 mm, max.: 1,500 mm

- Inner diameter: min. 25 mm

- Maximal cast weight: 3.3 t

- Maximal cast length: 5 m

- Maximal length: 8 m (welded construction)

Components

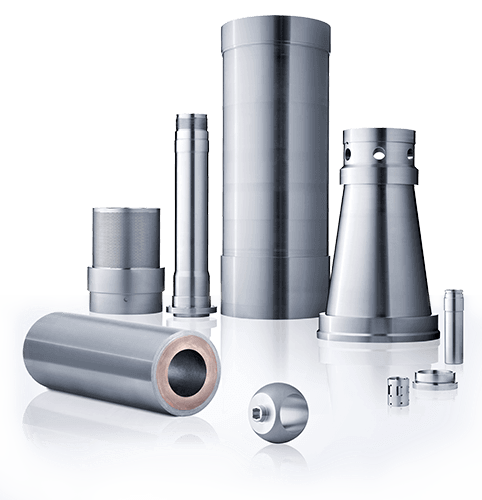

Conical and cylindrical drum casings, worm-feed assemblies and components, seal covers, bulkheads, seal mountings, tubes, bushings, rings

Special requirements of the materials used

Depending on application: extreme toughness, high corrosion-resistance, high wear-resistance, good welding properties

Material groups

Duplex steels (standard duplex, lean duplex, high-carbon duplex, super duplex), austenitic, nickel-based alloys

Materials

1.4470 ( 1.4462 ), 1.4463, 1.4408 ( 1.4401 ), 1.4409 ( 1.4306 ), 1.4308 ( 1.4301 ), 1.4309 ( 1.4306 ), 1.4392 ( 1.4362 ), 1.4469 ( 1.4410 ), J93371 ( 1.4460 ), 1.4468, 2.4836, N26022, N24135, 1.4581 ( 1.4571, 1.4580 )*

* Materials listed in italics are those that consist of our material-matched forged alloys

We are happy to answer your questions on the subjects of stainless steel processing and manufacture components according to your ideas for decanter construction, shipbuilding, engine construction and much more.

Just contact us

+49 (0)2195 92988-0

infonothing@kuhn-zerspanungstechnik.com